Cleaning Produce Washing Equipment: Brush Washer Conveyor System Checklist

Robert Hadad, Extension Vegetable Specialist

Cornell Vegetable Program

As we learn more about reducing microbial risk on the produce farm, more emphasis is being placed on cleaning food contact surfaces. Accessing the hard to reach spaces in wash line equipment is challenging. Most of the equipment was not made to come apart very easily or in an economically efficient manner. The checklist provided here has been developed through hands-on research cleaning equipment as thoroughly as can be measured without doing microbial testing. That level of cleaning is still being researched but, from our work, the level of cleanliness provided here appears to be sufficient.

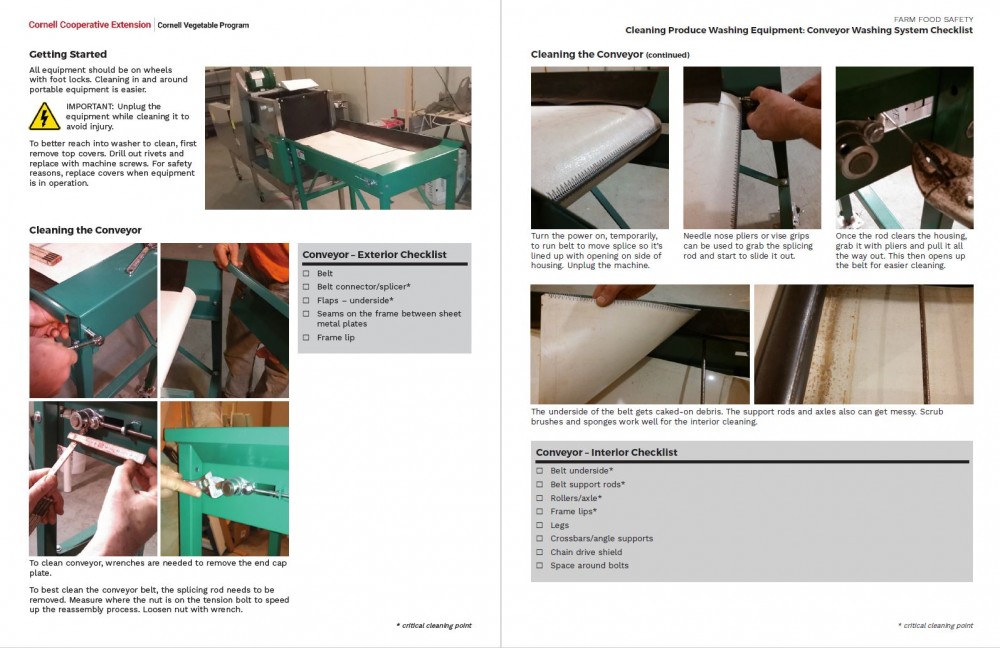

This step-by-step checklist provides visual guidelines and suggestions for reasonably cleaning your equipment.

The presentations found below provide more photos of the steps of cleaning the conveyor, the brush washer, and the absorber.

Cleaning Produce Washing Equipment: Conveyor Washing System Checklist (pdf; 1693KB)

Presentation: Cleaning the Conveyor in a Brush Washer System (pdf; 2036KB)

Presentation: Cleaning the Brush Washer in a Brush Washer System (pdf; 1833KB)

Presentation: Cleaning the Absorber in a Brush Washer System (pdf; 2114KB)

Upcoming Events

Vegetable Pest and Cultural Management Field Meeting for Auction Growers -- Ontario Produce Auction

July 15, 2025

Stanley, NY

This evening meeting will demonstrate pest management in fresh market vegetables in both field and greenhouse (high tunnel) vegetables, primarily for those growing for wholesale auction. A hands-on demonstration of weed, insect and disease identification in vegetables including management options. Details on each topic will focus on field observations at the farm.

Orleans Summer Vegetable Meeting, 2025

July 16, 2025

Waterport, NY

Meeting themes are pest management in a wide array of produce and best practices for pesticide use. Professor Brian Nault will cover allium leaf miner and thrips in onions, garlic, and leeks, and discuss insect challenges in other crops. Bring your questions! We'll also have a field walk that includes high tunnel tomato and cucumber.

DEC credits available: 0.5 in CORE plus either 1.25 in 1a and 23, or 0.75 in 24.

Vegetable Pest and Cultural Management Field Meeting for Auction Growers -- Finger Lakes Produce Auction

July 18, 2025

Penn Yan, NY

This evening meeting will demonstrate pest management in fresh market vegetables in both field and greenhouse (high tunnel) vegetables, primarily for those growing for wholesale auction. A hands-on demonstration of weed, insect and disease identification in vegetables including management options. Details on each topic will focus on field observations at the farm.